- Automated and self-contained pressure generation and control to 1,000 psi ( 70 bar)

- Standard accuracy to 0.02%FS

- Optional precision accuracy models to 0.01%FS

- Two removable internal pressure modules for multi-range selection

- Control stability to 0.003%FS

- Portable, designed for use in the field and in the lab

- Ability to measure two external pressure modules

- Wi-Fi, Bluetooth, USB and Ethernet communication

- HART and profibus communication

- Data logging and task management

- Patented electric pump technology and improved speed

-

-

• Fully automatic calibrator with built-in pump and controller

• Switchable internal pressure modules for expandable ranges • Accuracy (1 year) of 0.02%FS • External pressure modules available (measure only) • Less than 4 lbs (1.8 kg) for handheld operation• Source pressure, measure pressure and electrical • 4 channels • Optional HART communications • Optional data logging and task documenting • USB, Wi-Fi, and Bluetooth communications • ISO 17025-accredited calibration w/data included **COST WILL VARY BASED ON CONFIGURATION - PLEASE REQUEST A QUOTE FOR ACTUAL COST** -

• Fully automatic calibrator with built-in pump and controller • Switchable internal pressure modules for expandable ranges • Accuracy (1 year) of 0.02%FS • External pressure modules available (measure only) • Less than 4 lbs (1.8 kg) for handheld operation• Source pressure, measure pressure and electrical • 4 channels • Optional HART communications • Optional data logging and task documenting • USB, Wi-Fi, and Bluetooth communications • ISO 17025-accredited calibration w/data included **COST WILL VARY BASED ON CONFIGURATION - PLEASE REQUEST A QUOTE FOR ACTUAL COST**

-

• Pressurize large-volume workload • Generate pressure to 60,000 psi (4,200 bar) pressure • Increase and decrease pressure smoothly • Two pressure ports

-

• Fully automatic calibrator with built-in pump and controller

• Switchable internal pressure modules for expandable ranges • Accuracy (1 year) of 0.02%FS • External pressure modules available (measure only) • Less than 4 lbs (1.8 kg) for handheld operation• Source pressure, measure pressure and electrical • 4 channels • Optional HART communications • Optional data logging and task documenting • USB, Wi-Fi, and Bluetooth communications • ISO 17025-accredited calibration w/data included **COST WILL VARY BASED ON CONFIGURATION - PLEASE REQUEST A QUOTE FOR ACTUAL COST** -

The Type T tester is a dead weight tester that offers laboratory accuracy in an instrument designed to withstand an industrial environment or daily stresses of a manufacturing environment. Each tester features a re-entrant type measuring piston and cylinder assembly. This design reduces the rate of fluid leakage and increases float time, helping to maintain accuracy as test pressures increase. • Accuracy to 0.015% of reading • Ranges to 15,000 psi • Available in psi, kg/cm², bar, and kPa • Small incremental weight sets available. A dual volume pumping feature allows a large volume of fluid to be added at low pressures to fill the system and increase pressure rapidly. Once filled, switch to a smaller volume to easy pumping and provide finer control at higher pressures. • Overhung weight carrier reduces side thrust and friction • Over-pressure protection prevents piston damage • 3- leg design with bulls-eye leveling system • Single and dual column versions available to meet a wide variety of applications **COST WILL VARY BASED ON CONFIGURATION – PLEASE REQUEST A QUOTE FOR ACTUAL COST**

-

The PK II floating ball type pneumatic dead weight tester is engineered to offer user-friendly, safe operation. The easy-to-use primary standard provides reliable and accurate pressure measurement in the field, or in a lab. • Accuracy to 0.015% of reading • Ranges to 30 psi • Available in psi, g/cm², bar, mbar, kPa, inH₂O, cmH₂O, and mmHg • Small incremental weight sets provide fractional output pressure Featuring a self-regulating design, that allows automatic stabilization of weights, eliminating the need to adjust input pressure. • Rugged ceramic measuring ball • Overhung weight carrier reduces side thrust and friction • Quick-leveling system for field use • Optional TripodLocal gravity and standard gravity (980.665 gals) versions available.**COST WILL VARY BASED ON CONFIGURATION – PLEASE REQUEST A QUOTE FOR ACTUAL COST**

-

• Pressure ranges from vacuum to 3,000 psi (200 bar) • Precision accuracy models to 0.01% of reading • Standard model accuracy of 0.02% of full scale • HART Communication and Profibus PA • Control stability of 0.003%FS • Easy-to-use icon based user interface • ISO 17025-accredited calibration w/data included **COST WILL VARY BASED ON CONFIGURATION - PLEASE REQUEST A QUOTE FOR ACTUAL COST**

-

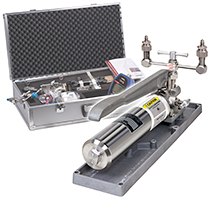

Calibration lab in a box! This portable gauge and transmitter calibration system is 7 to 10 times faster than a deadweight tester. It allows you to do a 10 point up and down calibration in less than 3 minutes including printing out a calibration certificate. • Gauge / Chart recorder / Transmitter calibration system • 7 to 10 times faster than a deadweight tester • Reduce transcription / calculation errors • 0.1% of reading accuracy up to 15 000 psi (1000 bar) when using the XP2i as the reference or 0.05% of reading accuracy up to 5000 psi (300 bar) when using the 30 Series as the reference • Easy to use and install, wizards guide you through setup • Includes a weather-proof rolling case that can be used as a portable bench

Automated Gauge Calibration System. Pressure Standards are extra. Includes GaugeCalHP, FastCalXP, NPT CPF Fittings, Fine Adjust, Footswitch, Carrying Case, USB Adapter, and Rebuild Kit. -

• Pressurize large-volume workload • Generate pressure to 40,000 psi (2,800 bar) pressure • Increase and decrease pressure smoothly • Three pressure ports

-

Perform both ultra-precise low pressure differential or high pressure static pressure calibrations with nitrogen using the same device. Self contained nitrogen source, regulator, precision fine adjust, hoses, gauge adapters and process connections provide a complete pressure control solution for doing nitrogen calibration of pressure instruments in remote locations. Self contained unit provides a precise nitrogen source for calibrating differential and static pressure instrumentation using an external pressure calibrator Proprietary pressure balanced fine adjustment piston allows for extremely precise, finger-tip control of pressure at 0.03 psi (2 mbar) or 3000 psi (210 bar) or any range in between. Easily refillable nitrogen cylinder holds enough gas for multiple calibrations Nylon bag to hold hose and fittings attached to inside of lid Includes storage compartment in control panel for pressure reference test gauge Low volume Quick-test hose, gauge adapter and process connection can be attached to NPAK without thread sealant or a wrench Designed to meet US Department of Transportation (DOT) and Canadian Transport Canada (TC) standards CE Approved for use in European Union - Designed to meet Pressure Equipment Directive (PED) and Transportable Pressure Equipment (TPED) standards Made in USA

-

• Generate 3,000 psi (200 bar) in 40 seconds • Minimal maintenance • Hand-tight quick connectors • First one in the world

-

Fast, portable, and easy – generate pressure to 15 000 psi The GaugeCalHP (System G) is a portable, self-contained, hydraulic pressure generator for calibrating pressure gauges, transmitters, sensors, and safety valves. It’s much faster than deadweight testers and most automated pressure controllers; and it’s so quick and easy to use, it’s ideal for calibrating those low cost gauges that are often overlooked for ISO9000 compliance. • Pressure to 15 000 psi / 1000 bar / 100 MPa • Vacuum to -12.5 psi / -0.8 bar / -86 kPa Use without fluid to generate up to 400 “H2O (995 mbar) to within 0.01 inches (0.025 mbar). Makes calibrating differential pressure transmitters easy. • Easily test large size gauges with the unique pivoting manifold • Quickly bleed air and capture fluid with the no mess drip tray • Gauge-safe integral venting system prevents damage to mechanical gauges • Use with water, light oil, or air

-

• Pressurize large-volume workload • Generate pressure to 15,000 psi (1,000 bar) • Increase and decrease pressure smoothly • Three pressure ports • Hand-tight quick connectors

-

Type T hydraulic comparator (System F) is a self-contained high volume pressure source capable of producing pressure up to 15 000 psi. It is ideal for testing gauges and setting hydraulic relief valves and pressure switches. Multiple models are available for hydraulic oil, water, or both. • Pressure Range: 0 to 15 000 psi • High and low volume settings • Two outlet ports • Large fluid capacity • Fine adjustment up to 3500 psi • Compatible with water and oil • T-1-CPF includes CPF fittings

-

• Minimal maintenance • Increase and decrease pressure smoothly • Three pressure ports • Hand-tight quick connectors